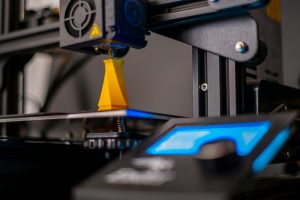

If you’re new to 3D printing, you’ve probably heard of G-Code, but what does it really do? And how can it affect the quality of your final print, even if you’re using high-quality PLA filament from PlaSpool?

Let’s break it down in simple terms.

What Is G-Code, Really?

G-Code is the language your 3D printer speaks. Every time you slice a model (using software like Cura, PrusaSlicer, or Bambu Studio), that software creates a list of instructions for your printer, and that list is G-Code.

It tells your printer things like:

- Where to move the nozzle

- What temperature to heat the nozzle and bed

- How fast to print

- When to retract or stop extrusion

Think of it as the recipe behind every print.

Why G-Code Matters for Print Quality

Even if you’re using the best filament in Nigeria, like PlaSpool PLA, poor G-Code settings can ruin your results. Here’s how:

1. Layer Height and Detail

- A lower layer height in your G-Code produces finer detail.

- Too high? Prints look rough or blocky.

2. Temperature Settings

- G-Code controls the nozzle and bed temperature.

- If the temps are too low for your PLA, the layers won’t stick properly.

- Too high, and you’ll get blobs or stringing.

3. Speed and Flow Rate

- Printing too fast = messy results or weak adhesion.

- G-Code adjusts speed line-by-line, so optimizing it helps even a basic printer produce pro-level results.

4. Retraction Settings

- Retraction tells your printer when to pull back filament to avoid stringing.

- Get it wrong, and you’ll get wispy strings or nozzle jams, even with premium filament.

The G-Code And Filament Connection

A lot of people blame the filament when prints fail, but often, it’s the G-Code settings.

Using high-quality, moisture-free PLA like PlaSpool ensures your material performs consistently. But to get great results, you need G-Code that matches the filament’s strengths.

Your slicer has built-in profiles, but for the best print quality, consider tweaking:

- Print speed: 50–60 mm/s for PLA

- Retraction: 0.8–1.2 mm at 30–40 mm/s

- Cooling: Keep the part cooling fan ON for sharp details

- Shells/walls: 2–3 walls for stronger parts

See more: FDM vs Resin Printing: Which Is Better for Beginners?

G-Code is more than just “tech stuff”, it’s the invisible force behind your print quality. When you combine optimized G-Code with locally produced, high-performance 3D filament like PlaSpool PLA, you get clean, strong, and reliable prints every time. Mastering G-Code is a simple way to step up your 3D prints, without upgrading your hardware.

Frequently Asked Questions

What is G-Code in 3D printing?

G-Code is the set of instructions your 3D printer follows to create an object. It tells the printer where to move, how fast, what temperature to use, and how much filament to push out. Think of it as the “language” your printer understands.

Does bad G-Code really affect my print quality?

Yes, poor G-Code settings can lead to stringing, blobs, weak layer adhesion, under-extrusion, or even failed prints.

Do I need to learn to write G-Code manually?

Not at all. Most beginners use slicer software to generate G-Code automatically. However, learning the basics can help you troubleshoot problems or tweak your printer’s performance.

Can G-Code cause clogs or filament jams?

Indirectly, yes. If your G-Code has incorrect temperature, over-retraction, or too-fast movement, it can lead to filament issues, even with quality materials. That’s why tuning your G-Code is just as important as using the right filament.