If you’ve ever looked into 3D printing, chances are you’ve seen two main types of printers pop up: filament-based (FDM) and resin-based stereolithography (SLA) and digital light processing (DLP). Both are capable of creating amazing things, but they work in completely different ways, and each has its own strengths and weaknesses.

What Is FDM 3D Printing?

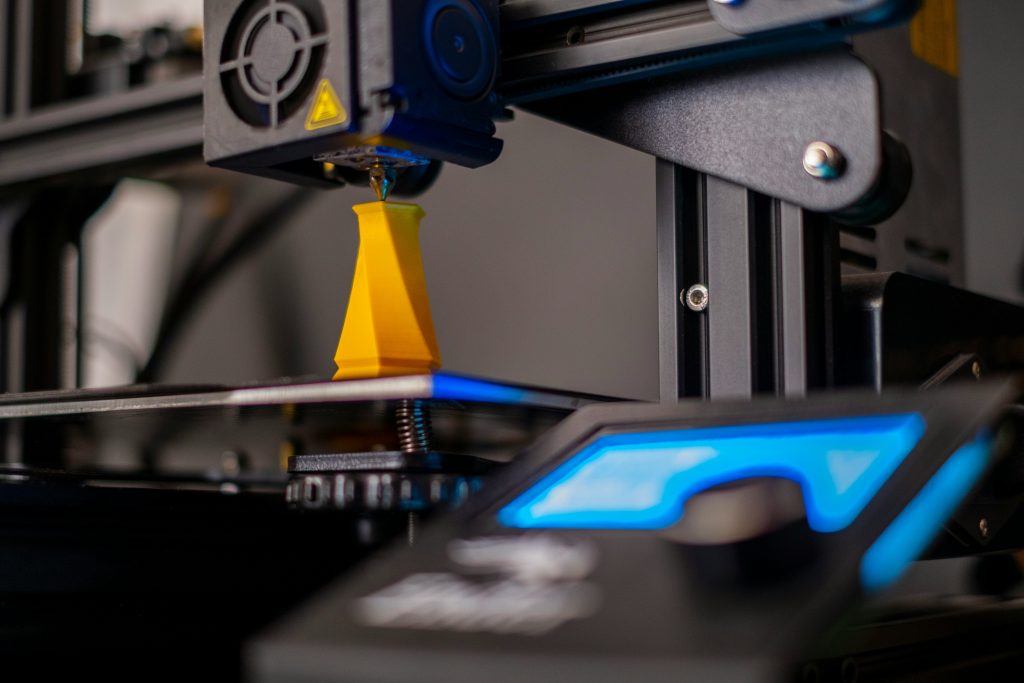

FDM stands for Fused Deposition Modeling, but all that really means is: your printer melts plastic and lays it down, layer by layer, to build your model. Think of it like a hot glue gun controlled by a robot.

This is the type of 3D printing most people start with. It’s reliable, budget-friendly, and relatively easy to learn.

Why Do People Love It?

People love filament 3D printing for a few good reasons. It’s great for entry-level printers and is often recommended as the best filament-based 3D printing method for beginners in Africa. It’s also strong, making it ideal for practical items like brackets, tools, and functional prototypes. The material options are flexible too; you can print with everything from soft, rubbery filaments to tough, impact-resistant ones. Plus, it’s generally safer to use, especially if you stick with beginner-friendly plastics that don’t produce toxic fumes or require special handling.

If you’re new to 3D printing in Nigeria or want to print practical, functional parts, FDM is an excellent starting point.

What About Resin 3D Printing?

Resin printing uses liquid photopolymer that cures under light. Your model appears as if by magic, rising upside down from a pool of resin, layer by layer.

This method is known for its stunning detail and ultra-smooth surfaces.

What Makes It Stand Out?

Exceptional detail makes it perfect for miniatures, jewelry, dental models, and intricate designs. It also offers a smooth surface finish, requiring less sanding and post-processing than FDM prints.. DLP printers cure entire layers at once, making them efficient for tiny components.

But resin printing comes with trade-offs:

Messy post-processing – Requires washing prints in alcohol and curing under UV light.

Toxic fumes and skin contact risk – You need gloves, masks, and proper ventilation.

More expensive – Resins, replacement parts, and accessories add up.

Fragile parts – Prints are detailed, but often brittle.

Resin vs FDM 3D Printing in Nigeria: Which Should You Choose?

| Feature | FDM (Filament) | SLA/DLP (Resin) |

|---|---|---|

| Print Detail | Moderate | High |

| Durability | Strong | Brittle |

| Ease of Use | Beginner-friendly | Intermediate to Advanced |

| Material Cost | Lower | Higher |

| Setup & Safety | Simple & Safe | Requires PPE & ventilation |

| Print Size | Larger prints possible | Small prints only |

| Ideal For | Functional parts, prototypes, and hobby use | Miniatures, jewelry, high-detail models |

Resin printing, while powerful, is more niche and better suited for designers and professionals who need extreme detail and are prepared for the extra handling requirements.

If you’re looking to print durable, cost-effective models with materials you can find locally, filament 3D printing is your best bet. But if your work demands ultra-fine detail, like in figurines or dental applications, resin printing is unmatched in precision.

Both technologies are powerful. The best one depends on your goals, budget, and workspace. And in a growing African 3D printing market, there’s room for both.

Both printing methods are amazing, but only when matched with the right project.

- Filament is your go-to for strong, functional, everyday printing.

- Resin is your weapon of choice for sharp detail and beautiful finishes.

See more: How to Glue PLA, PETG & ABS 3D Prints

Need 3D Filaments In Nigeria? We’ve Got You Covered

Our premium 3D filament line is coming soon to Nigeria and West Africa. Join our waitlist and be the first to shop when we launch!