What Are 3D Printer Filaments?

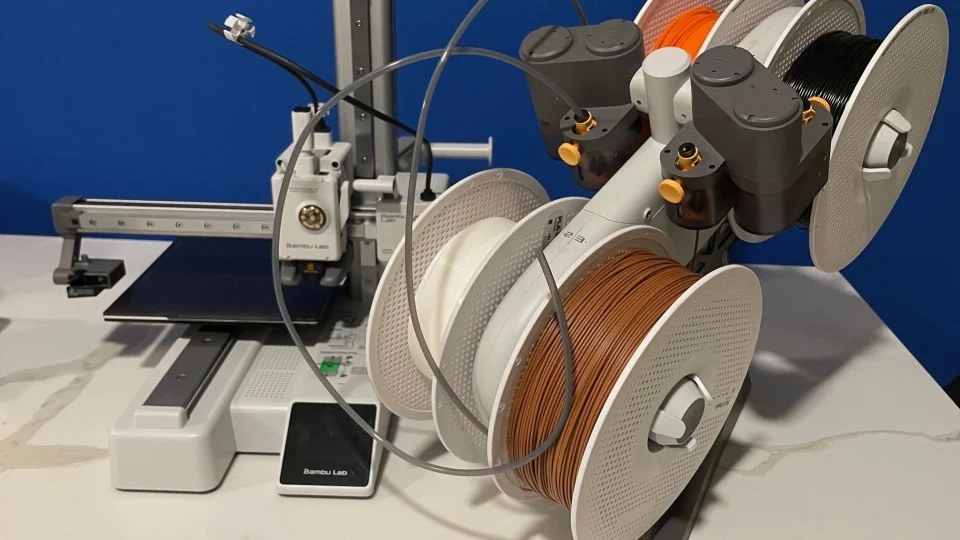

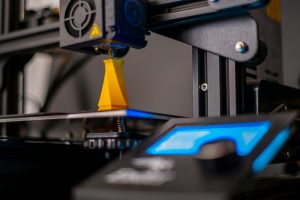

3D printer filaments are the materials used in FDM (Fused Deposition Modeling) 3D printers. Think of them as the “ink” for your printer, but instead of liquid, they come as long strands of thermoplastic wound onto spools. When heated, these filaments melt and are extruded layer by layer to create solid, three-dimensional objects. Available in standard diameters of 1.75mm or 2.85mm, filaments vary widely in strength, flexibility, temperature resistance, environmental impact, and cost.

3D filaments come in different types, each with its own characteristics like strength, flexibility, durability, temperature resistance, and appearance. Choosing the right 3D filament can make a huge difference in the quality and performance of your 3D print.

If you’re getting into 3D printing in Nigeria, especially from growing tech hubs like Abuja or Lagos, one of the most important choices you’ll make is selecting the right filament. Whether you’re printing for personal projects, business prototyping, or educational uses across Africa’s expanding 3D print industry, the material you use can make or break your results.

This guide breaks down the most common 3D filament types, helping you decide which one best fits your needs and your 3D printer.

Factors To Consider When Choosing 3D Filament

Before diving into 3D filament types, here are essential factors to evaluate:

- Material Strength & Flexibility

- Print Temperature Compatibility

- Heated Bed Requirements

- Post-Processing Capability

- Environmental Friendliness

- Cost & Availability in Nigeria or Africa

See more: How Does 3D Printing Work? A Beginner’s Guide

Common 3D Printing Filament Types

PLA (Polylactic Acid)

Best for: Beginners, prototypes, decorative prints

Pros:

- Easy to print, low warping

- Great detail and layer adhesion

- Biodegradable and made from renewable resources

Cons:

- Low heat resistance (~60°C)

- Not suitable for outdoor or functional parts

ABS (Acrylonitrile Butadiene Styrene)

Best for: Functional parts, enclosures, engineering applications

Pros:

- High strength and impact resistance

- Withstands higher temperatures (~105°C)

- Can be acetone smoothed for a glossy finish

Cons:

- Warps easily without an enclosure

- Releases fumes during printing – ventilation required

PETG (Polyethylene Terephthalate Glycol)

Best for: Durable, moisture-resistant parts

Pros:

- Strong and flexible

- Water- and chemical-resistant

- Great layer adhesion

Cons:

- Can string if retraction isn’t tuned

- Slightly less detail than PLA

TPU / TPE (Flexible Filaments)

Best for: Wearables, phone cases, seals, vibration dampening

Pros:

- Highly elastic and abrasion-resistant

- Shock-absorbent

- Shore hardness range: 35A (very soft) to 95A (firm rubber-like)

Cons:

- Requires slower print speeds and direct-drive extruder

- Can be tricky for beginners

Nylon

Best for: Engineering, gears, load-bearing parts

Pros:

- Strong, flexible, wear-resistant

- Good chemical resistance

Cons:

Requires high-temp printing

Absorbs moisture – must be stored dry

Specialized & Engineering-Grade 3D Filaments

Polycarbonate (PC)

- Extremely durable and heat-resistant

- Ideal for high-impact or heat-exposed parts

- Requires very high print temperatures (260–310°C)

Carbon Fiber-Filled Filaments

- Blends like PLA+Carbon or Nylon+Carbon

- Lightweight and stiff with minimal warping

- Abrasive: needs hardened nozzle

Metal-Filled Filaments

- PLA blended with bronze, copper, or steel

- Heavier, polishable

- Ideal for jewelry, artistic parts

PVA (Polyvinyl Alcohol)

- Water-soluble support for dual extrusion

- Great for complex overhangs and internal channels

Eco-Friendly & Sustainable Filaments

PLA & PHA

- Made from cornstarch, sugarcane

- Compostable in industrial facilities

Recycled Filaments (PETG, PLA)

- Produced from plastic waste

- Ideal for cost-effective and conscious printing

Wood / Algae / Bio-Mix

- Natural textures

- Great for product design and sustainable prints

Filament Strength & Durability Comparison

| 3D Filament | Strength | Flexibility | Temp Resistance | Ease of Use |

|---|---|---|---|---|

| PLA | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ | ★★★★★ |

| ABS | ★★★★☆ | ★★★☆☆ | ★★★★☆ | ★★☆☆☆ |

| PETG | ★★★★☆ | ★★★☆☆ | ★★★☆☆☆ | ★★★★☆ |

| Nylon | ★★★★★ | ★★★★☆ | ★★★★☆ | ★★☆☆☆ |

| TPU/TPE | ★★☆☆☆ | ★★★★★ | ★★★☆☆☆ | ★★☆☆☆ |

| PC | ★★★★★ | ★★☆☆☆ | ★★★★★ | ★☆☆☆☆ |

Choosing the Right 3D Filament for Your Project

| Goal | Recommended 3D Filament |

| Getting Started | PLA |

| Functional Parts | ABS, Nylon, PC |

| Flexible Prints | TPU / TPE |

| Outdoor Use | ASA, PETG |

| Artistic Prints | Metal-Filled, Wood-Filled |

| Eco-Friendly | PLA, Recycled PLA or PETG |

Choosing the right 3D filament has a direct impact on the quality, cost, and success of your 3D print. As 3D printing in Africa expands across various industries, including healthcare, architecture, fashion, and engineering, understanding the materials is crucial to success.

Need 3D Filaments? We’ve Got You Covered

Our premium 3D filament line is coming soon to Nigeria and West Africa. Join our waitlist and be the first to shop when we launch!